Insert & Multi-Material Plastic Injection Molding

Since 1992, Innovative Components, Inc. has specialized in insert molding. Whether you require a custom molded part or a selection from our extensive line of proprietary plastic clamping knobs and handles, Innovative Components has the skills and experience needed to deliver high quality parts on time. We utilize the most advanced rotary presses in the industry with multiple cavity tools. The sophistication of our equipment has allowed us to minimize set-up time and in-process adjustments, maximizing output. Our plant in Cartago, Costa Rica operates 24 hours/day, 5-7 days per week, striving for optimum capacity and economically absorbing overhead. This high capacity production enables us to offer our customers with the competitive pricing expected in today’s global marketplace without the risks inherent in import sourcing.

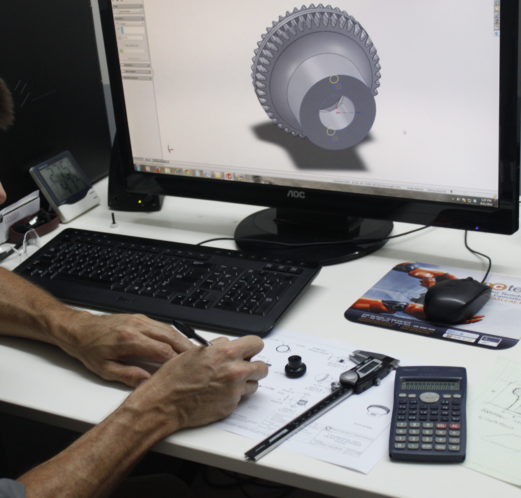

Design & Engineering

Our staff of skilled mechanical engineers utilizes state of the art 3-D CAD software to find the best solutions for our customers and to support our drive for constant innovation.

Tool Design, Mold Making & Maintenance

Innovative is expert at making plastic injection molding tools 100% in house in our Costa Rican factory. Looking for a custom molded plastic component? Work with our skillful designers to develop your 3D model and tool design. Then, employ our experienced tool makers to bring your vision to life. Our state of the art tool room is equipped with CAD/CAM software, CNC and EDM Machines, heat treat ovens, laser etchers, precision polishers, acid texturing, sand blasting, milling and grinding equipment. Discuss you next custom molded part with Innovative’s technical sales people today.

CNC Swiss Machining

Whether you need a  custom machined component or special inserts for one of our offerings from our extensive line of plastic clamping knobs, Innovative Components can deliver high quality parts and attractive prices. We have recently added CNC Swiss Machining equipment to our factory in Cartago, Costa Rica. The lower labor rates of Central America and short transit times allow us to give our customers significant savings with competitive lead times. For immediate needs, we can utilize our domestic CNC machine for a quick turnaround.

custom machined component or special inserts for one of our offerings from our extensive line of plastic clamping knobs, Innovative Components can deliver high quality parts and attractive prices. We have recently added CNC Swiss Machining equipment to our factory in Cartago, Costa Rica. The lower labor rates of Central America and short transit times allow us to give our customers significant savings with competitive lead times. For immediate needs, we can utilize our domestic CNC machine for a quick turnaround.

Light Assembly

Our light assembly department specializes in producing manually assembled hardware components such as pins, wire lanyards, latches, soft-tip fasteners, and more. Need a low cost alternative? Put our low cost Costa Rican assembly department to work on your assemblies. Our equipment in this area includes but may not be limited to hydraulic presses, punch presses, arbor presses, manual mills, pad printers, laser etchers, wire cutters, wire strippers, digital glue dispensing machines, impulse sealers, bagging and packaging equipment.

Bagging & Kitting

For single component jobs we utilize our fully automated bagging machine. For more complex multi-component jobs, we undergo a more manual process using our secondary operators with assistance from the automated bagger. This state of the art machine is capable of printing bar codes, part numbers, logos, pricing, or anything you wish. If you are including our knobs in any kits you may be outsourcing, discuss consolidation and allowing Innovative to do your bagging today.

Pad Printing

Pad printing is a durable and attractive way to decorate plastic parts. Add logos, instructions, and safety warnings using a variety of substrates in single color or two color shot processes. Innovative’s team can design and manufacture clichés per your specification.

Laser Etching

Looking to permanently mark metal components with designs, part numbers, logos, lot numbers, or logos? Let Innovative put one of their laser etching machines to work for you. Contact sales today.

Secondary Machining & Assembly Operations

Our collection of lathes, mills, grinders, presses, drills and assorted other secondary equipments allow us to offer such options as tapping, pointing, shaving, drilling, slotting, cross-drilling, and crimping on fasteners and metal parts. In many cases, we can utilize a standard cold-formed fastener with secondary operations to reduce the cost versus custom machined parts. Low-cost labor in our Costa Rican factory makes us exceptionally competitive for labor-intensive operations.